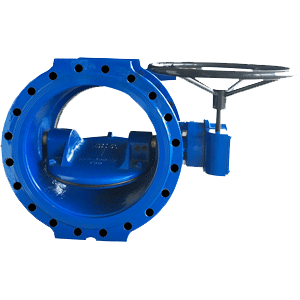

Double eccentric, double flanged butterfly valve is widely used in water, sewage water and air medium.

Mainly used in water plants, sewage plants, long-distance water transmission and municipal water distribution, as on-off valves.

Equipped with a hydraulic control actuator, it can be used to protect the pipe explosion in the dam, replace the check valve in the water plant to protect the opening and closing of the pump, and can also be used as shut-off protection valve in power plant air-cooling island.

Design acc. to EN 593

Face-to-face length: acc. to EN 558-1, basic series 14 (DIN 3202, F4)

With flange ends on both sides acc. to EN 1092-2

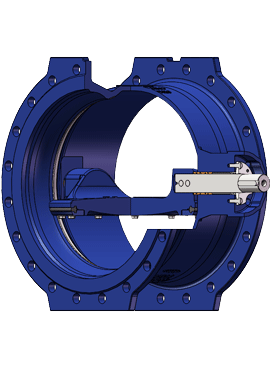

Maintenance-free bushing

Double O-ring sealing and blind screw holes disk

Corrosion-resistant and wear-resistant seat

Possible to replace sealing ring without disassembling the disk

The sealing ring adjusted automatically depending on the medium pressure to achieve bi-directional sealing

Unidirectional negative pressure sealing performance

Tight in both directions acc. EN 1074-2

Blow-out prevention valve shaft and dry shaft design

Maintenance free, self-locking worm gear, with mechanical position indicator

Anti-cavitation design according to the conditions of water plant, significantly improvement to the effect of cavitation

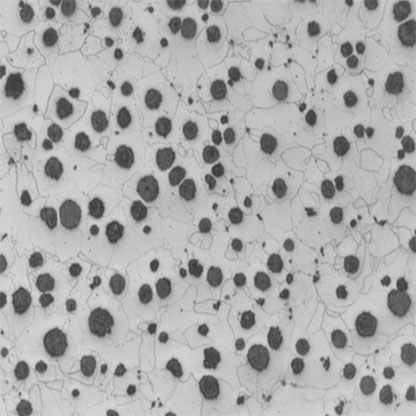

Body: ductile iron EN-JS 1030 (GGG40)

Disc: ductile iron EN-JS 1030 (GGG-40)

Sealing ring: EPDM/NBR/PTFE

O-ring: EPDM/NBR/PTFE

Shaft: stainless steel 2Cr13,304,316 or duplex stainless steel

Bushing: bronze

Stud & nut: stainless steel A2/A4

Handwheel

Electric actuator

Pneumatic actuator

Hydraulic control actuator

Body: internally and externally epoxy coated(comply with heavy corrosion protection practice for buried valve)

Disc: epoxy coated (rubber covered or nylon coated on request)